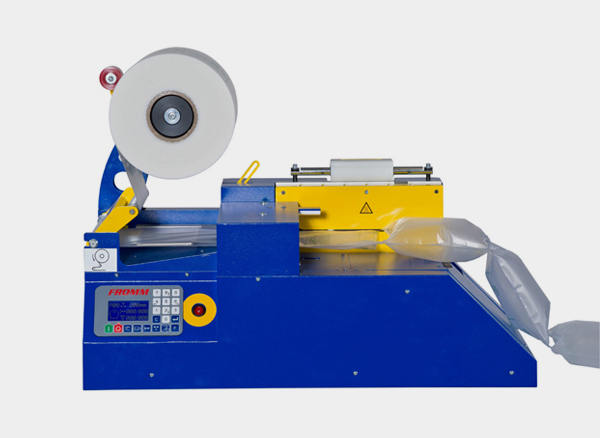

Air Pad Machine

AP 502 is fully automated and computerised Airpad machines which produce a sheet form of Air pillows of 6 different sizes from the same roll of film. These Air pillows are used for void filling in boxes to protect goods and because they are produced in a sheet format, are capable of being wrapped around larger items for complete protection during transit.

These machines are also programmed to create 45 different variations of the 6 sizes of Air Pillows which will allow our customers the freedom to create a pillow specifically geared to the product that requires transit protection at a touch of a button.

Features of the machine:

Industrial, heavy-duty design

45 variations of cushions with one film

Pre-set programs, easily selectable on screen

Wide range of films from 25 to 65 microns

Wide range of materials: PE, PE-PT, PE-PA, laminated, coextruded

AP 502 with integrated winder

Features of the machine:

Industrial, heavy-duty design

45 variations of cushions with one film

Pre-set programs, easily selectable on screen

Wide range of films from 25 to 65 microns

Wide range of materials: PE, PE-PT, PE-PA, laminated, coextruded

AP 502 with integrated winder

Air Pad Machine - AP 502

| MODEL | BRAND & ORIGIN | PORTABLE | NO. OF PROGRAMS |

|---|---|---|---|

| AP 502 | FROMM, Switzerland | Yes | 45 |

AP 250 The new table top machine in combination with a wide variety of standard or customised accessories offers customers an extensive range of applications:

Stand alone systems or integrated in multi-user workstations. The large number of programs allows to produce the most suitable Airpads for your product. Endless production or pre-programmed amount of pads in different film thicknesses and film qualities open a wide field of applications.

Features of the machine:

Long life design and rugged construction

Minimum of maintenance required

Easy Teflon changes

No compressor required

Easy to load film

Easy to operate

Adjustable air volume

Programmable lengths of air-chains

Programmable lengths of airpads

Features of the machine:

Long life design and rugged construction

Minimum of maintenance required

Easy Teflon changes

No compressor required

Easy to load film

Easy to operate

Adjustable air volume

Programmable lengths of air-chains

Programmable lengths of airpads

Air Pad Machine - AP 250

| MODEL | BRAND & ORIGIN | PORTABLE | NO. OF PROGRAMS |

|---|---|---|---|

| AP 250 | FROMM, Switzerland | No | 18 |

AP 100 The new and compact Airpad AP100 table top air pillow machine of Fromm is user friendly and ideal for decentralized packing stations.

The various pad sizes allow to produce the most suitable airpads for superior protection of products

Features of the machine:

User friendly

-Easy to operate

-Easy roll change

-Short start-up time

Ergonomic, integration with

-mobile bin

-Stand alone hopper

Highly reliable and low maintenance

Features of the machine:

User friendly

-Easy to operate

-Easy roll change

-Short start-up time

Ergonomic, integration with

-mobile bin

-Stand alone hopper

Highly reliable and low maintenance

Air Pad Machine - AP 100

| MODEL | BRAND & ORIGIN | FILM WIDTH | NO. OF PROGRAMS |

|---|---|---|---|

| AP 100 | FROMM, Switzerland | 200mm, 400mm | 10 – 16 meters / min |

AP 150 The new rapid Fromm’s compact bubble on demand system Airpad AP150 generates with high Speed 18 meters of film per minute. In addition the machine is very user friendly in execution and has good ergonomics with simple and reliable winder.

Features of the machine:

- Very user friendly

- Easy to connect

- Automatic starts and stops

- Fast generation of “bubble film” material

Features of the machine:

- Very user friendly

- Easy to connect

- Automatic starts and stops

- Fast generation of “bubble film” material

Air Pad Machine - AP 150

| MODEL | BRAND & ORIGIN | FILM WIDTH | NO. OF PROGRAMS |

|---|---|---|---|

| AP 150 | FROMM, Switzerland | 400mm | 18 meters / min |